Geplaatst op: 23 February 2026

Bestseller’s new distribution center (DC) in Lelystad is striking for its enormous amount of wood: 23,500 m³. However, wood isn’t the only material: steel and concrete also play a significant role, with sustainability and low CO₂ emissions being key priorities.

Sustainable design as a starting point

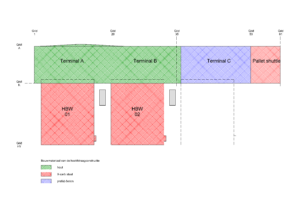

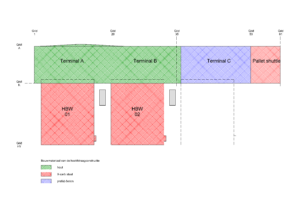

During the preparatory phase, Bestseller commissioned us to design a building with the lowest possible CO₂ emissions and to use bio-based materials wherever possible. The distribution center consists of several building sections with varying functions and loads. Therefore, the structural option with the lowest environmental impact was chosen for each section.

High-bay warehouses and section D: steel with a low environmental impact

Height and large spans were decisive factors for the high-bay warehouses and section D. Steel proved to be the most suitable construction method. Both steel structures are fully detachable and constructed of XCarb® steel, a type of steel with a low environmental impact.

Sections A and B: Timber Construction

In sections A and B, the superstructure is constructed entirely of timber. The floor load on the upper floors is 7.5 kN/m². Wood not only provides sufficient load-bearing capacity here but also contributes to the project’s biobased ambition.

Section C: Precast Concrete and Timber

Section C combines precast concrete floors with a timber roof structure. The floor load on the upper floors is 12.5 kN/m². This hybrid solution provides the necessary strength and stability, while the timber roof contributes to reducing CO₂ emissions.

Greyatter Industrial floors on HS-piles

All industrial floors are constructed of low-carbon concrete: Greymatter from Van Berlo. The Greymatter concept used here involves reducing the cement content through granular packing optimization. The industrial floors at ground level are founded on mini-vibrated piles. These are slender piles that are driven into the ground at high speed. These piles are only suitable for supporting the industrial floor and are not part of the main load-bearing structure. Besides being a highly cost-efficient system, this floor system also achieved the best LCA rating. This maximizes sustainability at the foundation level.

Although timber was not suitable everywhere, materials with the lowest possible CO₂ emissions were deliberately chosen for each section. In a future article, we’ll determine the building’s final LCA value and provide insight into the overall environmental performance of this unique distribution center. Stay tuned to our social media for another Bestseller update!

Geplaatst op: 25 July 2025

The first half of 2025 is over – and what a half year it was! We have been able to work on wonderful projects, together with our trusted partners as well as enter into new collaborations. That combination provides fresh ideas, new insights and plenty of energy. The result? A successful first six months that we look back on with pride.

Naturally, we have not let this go unnoticed. Together with the entire team of Pelecon Gouda and Pelecon Amersfoort, we celebrated this during a sporty and pleasant summer day at Chi Chi – The Golf Venue in Utrecht. We hit a ball, enjoyed good food and drinks, and thus ushered in the summer period together.

A period of relaxation, because after hard work it is time to enjoy well-deserved days off. Our office is therefore closed in weeks 32 and 33. From Monday 18 August we will be at your service again – with new energy and of course a fresh cup of coffee.

See you soon in Gouda or Amersfoort!

We wish everyone a very nice summer!

Henk van Vliet

Mack Stolwijk

& all colleagues from Gouda and Amersfoort

Geplaatst op: 8 February 2024

A classic example of an ambitious hard worker; that is our newest colleague Moutaz Bellah Ajjan. Over nine months ago, he started at our Gouda office in the role of structural modeler. A job that was tailor-made for him after completing his civil engineering studies at the Hogeschool Rotterdam. Together with our structural engineers, Moutaz ensures that drawings, models and calculations for various phases within projects can be delivered at Pelecon.

Moutaz came to the Netherlands in 2015 with a huge ambition to become a successful engineer. In doing so, he says: “falling is a new opportunity to stand up. Every time life frustrated me, I discovered that I had become stronger. I am a highly motivated person with great perseverance, someone with the will to get the best out of myself and succeed at all costs in everything I do.” How wonderful it is that we were able to add such a motivated colleague to our team!

The first period as a ‘Peleconner’

Moutaz explains that he was fully inducted into Pelecon in a short time. “My learning speed was helped by the experienced colleagues. The friendly atmosphere and helpfulness of all colleagues, combined with the informal corporate culture really appeal to me within Pelecon.”

The work of Moutaz

As an entry-level modeller, Moutaz works on all projects; after all, you gain experience by simply doing! Moutaz says he has developed a special interest in modelling distribution centres and steel structures. He also wants to delve more into that and we give him every opportunity to do so. Why Moutaz finds it so inspiring to work for such assignments? “Developing large distribution centres in a model is very challenging. It requires me to maintain an overview, both for myself and for my colleagues and our clients. Although; concrete structures are more complex and challenging, especially when it comes to the reinforcement of the structure (beams, floors, columns).”

Pride

“My pride is project Hall 6 for the Technische Unie in Alphen aan den Rijn. It was my first major project at Pelecon in which I was involved. We had to build a new hall to an existing hall. This project taught me an enormous amount about the entire project process; from A to Z.”

Want to know more about this project? Read the whole article on our news page.

Geplaatst op: 1 November 2023

TODAY IS THE 25TH ANNIVERSARY OF PELECON GOUDA! THAT MEANS 25 YEARS OF EXPERIENCE AS A CONSULTANT IN THE FIELD OF STRUCTURAL ENGINEERING. FOR 25 YEARS WE HAVE BEEN CALCULATING, DRAWING, CHECKING AND ADVISING ON LOAD-BEARING AND STABILITY STRUCTURES OF ARCHITECTURAL DESIGNS, SUCH AS DISTRIBUTION CENTERS, BUILDINGS, OFFICES, SHOPPING CENTERS, HOMES AND SCHOOLS. THAT IS WHY OUR ENTIRE PELECON TEAM IS CELEBRATING THIS AFTERNOON!

Pelecon Gouda was founded in 1998 by Wim van Leeuwen and Piet Peters; two men with a passion for building structures. Please find attached the newspaper article from the Rijn and Gouwe of Tuesday, September 22, 1998 about the registration of this fifty thousandth company in the Trade Register. Nice to know is that both Wim and Piet already had 25 years of experience in the structural engineering profession at the time. Enough knowledge on board, therefore, to start the successful Pelecon!

GROWTH OVER THE YEARS

Over the years, our services have only improved. For example, we have become strong in the field of logistics real estate, (food and dairy) industry and complex residential buildings. We also expanded our knowledge and capacity by merging with the 47 years of experience of engineering firm Reijneveld from Amersfoort in June 2021. From then on, we will have two offices, each with its own set of clients, but where the knowledge of people from Gouda and Amersfoort will be used back and forth! This enables us to learn from each other and keep up with current market developments.

NO PELECON WITHOUT CLIENTS AND PELECON PARTNERS

Thank you clients and partners for your trust over the past 25 years. But above all, thank you Peleconners for your loyalty and inspiration! On to the next 25 years of PELECON!

Our colleague Klaudia Wojtasik-Schoo went to an interesting theme day of our partners Nebest and Bouwen met Staal. During this day with the topic ‘Meten is weten’ (measuring means you know the size) the focus was on the reuse of steel. It is extremely important for us to attend such meetings because we want to stay up to date in all areas of construction. Because innovations, environment and sustainability are important spearheads in these times. Even within engineering, we at Pelecon are actively working on this.